LINER DATA IS THE MISSING LINK

Promet.ai is a team of collaborators from the mining, academic, and venture capital space trying to answer a big question: How can we understand processes more efficiently to accelerate mining’s energy transition and reduce operational carbon footprints?

We looked at the biggest emission question mark in the mining process and found our focus: the comminution space. While full mill operations need a complete overhaul, we believe that maximizing current infrastructure technology is not just critical, but necessary.

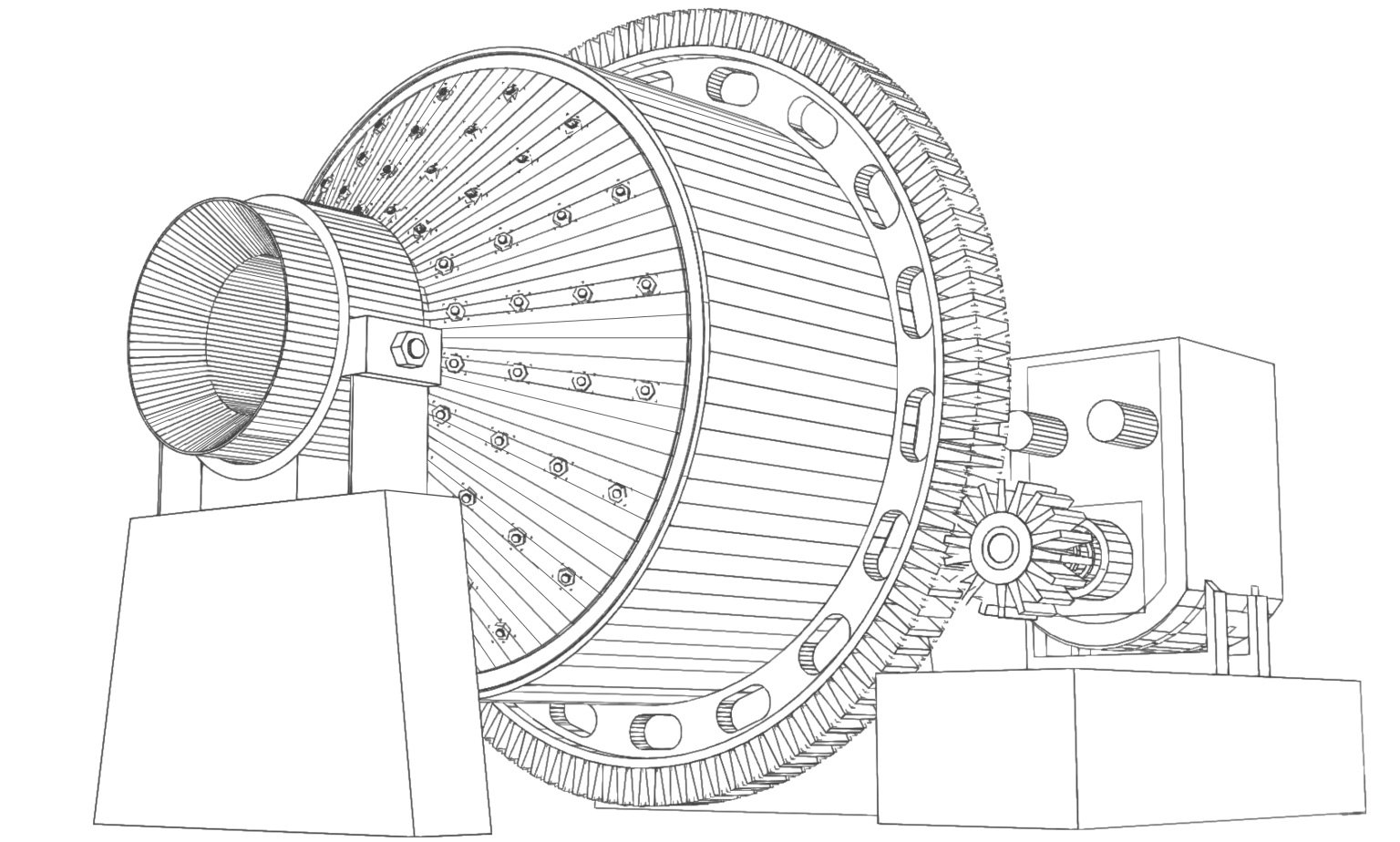

Together, we built sensor technology that acts as a “cochlear implant for your mill”: a way to understand liner wear measurement and mill analytics simultaneously without needing to shut off your operations.

Promet revolutionizes your sag, ag and ball mill technology to meet aggressive energy transition targets for the mining industry.

Immediate Solution Technology

Sensors with sub-mm resolution provide a real-time measurement of liner wear for your mill analytics.

Long-Term VISION

Fusion with other sensors for operational and maintenance optimization through real-time advanced process control and maintenance planning.

“When I first saw the concept presented of an instrumented SAG mill bolt that would allow online (at least daily) measurement of liner wear, I was excited that we would finally have a critical missing tool to be able to better understand both common cause and special cause wear drivers.

This is a key advance in unlocking the black box of SAG mill operations, and Promet intends to combine with other sensors to build an advanced process control platform to give much improved SAG mill operational performance.”